Kohler Kerber

By Kasy Long

May 1, 2023

Automation and Control Engineering Technology Major

at Indiana State University

When Kohler Kerber enrolled as an undergraduate student at another university, he knew something didn’t feel quite right. He wasn’t comfortable. He knew that campus was not the right school for him.

Kerber was destined to earn his bachelor’s degree elsewhere: Indiana State University.

The senior automation and control engineering technology student transferred to Indiana State for his sophomore year. Smaller class sizes allowed him to engage with his peers, receive individualized attention from his professors, and begin working in laboratory spaces and participating in other research opportunities immediately.

“The different majors are unique at Indiana State. I found a major [automation and controls engineering technology] that I had never seen before at other schools and it was exactly what I wanted to pursue as an engineer,” says Kerber. “From the small class sizes and unique programs, I knew Indiana State would be a better fit for me.”

Students in the automation and control engineering technology program prepare for high-demand careers in the automation field. Automation plays an important role in industrial machinery and processes and involves the use of computer-based control systems.

In laboratory classes, students work with computer numerical control [CNC] equipment, robotics, and logic controllers to study electronics and computer technology, manufacturing processes, mechanical engineering, and machining. Throughout the program, students develop their technology project management and teamwork skills to be used in internships and in their careers.

“The automation and control engineering technology program is challenging, but you find your niche. The classes cover everything you could want to know about automation engineering and control systems. You learn and discover what you’re going to love about your job. I knew this was the right industry for me,” Kerber explains.

In fact, Kerber knew at a young age that engineering was in his future. As a child, he enjoyed playing with LEGOs, and he watched his father work with industrial machinery. He developed a mechanical mindset and a love for electronics.

“I’ve always loved the automation side of engineering. I love the thought of making things more efficient and meeting the supply and demand of the industry,” he says.

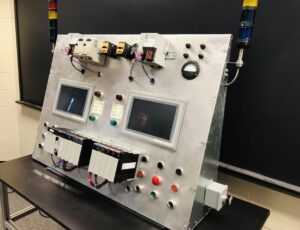

An example of an automation and control engineering technology design project Kohler Kerber worked on during his undergraduate education.

For his degree, the Sycamore worked closely with engineering professors David Malooley, Alister McLeod, PhD., and Ben Thompson in classes on fluid power, industrial electronics and control systems, and design projects. Kerber completed projects on programmable logic controller [PLC] programming, robot cells, designing programs for pharmaceutical assembly lines, and a senior capstone project correlating with his internship at Crown Equipment Corporation, a global manufacturer of material handling equipment, lift trucks, and other technology.

For the internship, Kerber assisted in the production of counterweights for Crown forklifts. The experience inspired the Sycamore to focus his senior capstone project on the production and technical maintenance of an insert press for the counterweight mold and casting processes for lift trucks.

Following graduation in May, Kerber will begin working full time at Crown Equipment as an assembly manufacturing engineer in the special projects division in Celina, Ohio.

The Sycamore credits the challenging curriculum in his automation and control engineering technology program, as well as his professors and peers, for encouraging him to ask questions, solve problems, and find the right industry for his future.

“Once you find your niche and what you like in engineering, that’s a spark and it keeps going. You find what you really want to do with your job. At Indiana State, you collaborate with your peers and professors on projects, and they are always there to support you,” Kerber says.

The Sycamore also collaborated with his peers in student organizations, including the American Society of Mechanical Engineers, in which he learned more about teamwork. “You will work with people when you’re an engineer, so it’s important to begin working with your classmates so you can build those important teamwork and leadership skills,” he adds.

Kerber compared the learning process at Indiana State to a seed growing into a tree. “This is the time to ask questions and get out of your shell. Start small now and you’ll eventually grow and evolve to success,” he explains.

Building toward career success is similar to the LEGOs Kerber played with as a child. It just takes one step – or brick – at a time to construct something great. Through collaborating on design projects and other real-world learning experiences, Kohler Kerber is building his professional future. Because real engineers wear BLUE!