Alex Badillo

By Indiana State University

Jun 18, 2020

Quarantine forces people to live differently, which for Dr. Alex Elvis Badillo, an Indiana State University assistant professor of earth and environmental systems (EES), has meant bouncing between teaching his courses online by day and 3D printing ear savers for surgical masks in his garage for Vigo County’s frontline workers by night.

The latter was done first at the request of his former student and anthropology major, Madeline Riley, ’19.

“She saw on social media that the online 3D printing community had begun to print out the surgical mask ear saver devices in an effort to contribute to healthcare and essential worker relief during the pandemic,” Badillo said. “Last year she was involved in my lab, the Geospatial and Virtual Archeology Laboratory and Studio, where she knew that we used 3D printing methods for public outreach and educational purposes, so she brought (the idea) to my attention at first by tagging me on a Facebook post.”

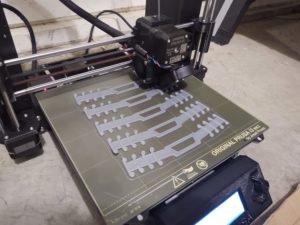

The request peeked Badillo’s interest, so he downloaded the National Institutes of Health facemask ear saver files and used a free slicing software that slice the 3D model into information that the 3D printer can understand. Then the information is sent to the 3D printer where it is printed using plastic material. The ear saver devices are said to reduce tension behind the ear that is caused by typical facemasks.

He created and donated 75 of the ear savers to the Vigo County Health Department, but his efforts didn’t stop there.

Badillo teaches a course called Archeological Methods: 3D documentation for science within the EES department at ISU. During a Zoom lecture on 3D printing as a tool for visualization, Badillo showed his students how to print 3D masks and other devices using the National Institutes of Health website. Matt Deady, a student in the class and a quality intern at Clabber Girl, brought the concept of 3D masks to his boss and the president of Clabber Girl.

“As an intern, I couldn’t help but notice how many production workers were having issues with the masks we provided, particularly it hurting their ears and face,” Deady said. “When the issue emerged among the production workers I recalled the live class session with Dr. Badillo about the ear savers, and reached out to him about accruing some.”

Clabber Girl purchased 300 masks for their staff and the proceeds will be used for ISU’s new visualization classroom and makerspace in the Science Building, where the 3D printers will be stationed once classes resume on campus.

By the end of April, Badillo was able to fill the order for Clabber Girl. According to Badillo, it takes about 80 minutes to produce five ear saver devices on a single printer. Using two 3D printers, he was able to print about 100 devices per day. He produced 300 in three days. Currently, Badillo has 100 more ear savers to send out to places who could use them.

“I was simply showing my students in my class how we could use the printers, so I’m glad we could help in this way,” he said. “Our department prepares students for careers in both academia and the industry teaching valued skills in state of the art visualization techniques and 3D technologies. Innovative visualization technologies are advancing rapidly and are already beginning to be used in most industries, so the new visualization classroom and makerspace gives our students hands-on training with these technologies.”